From the heart of Motor Valley, Costamp Group designs and manufactures molds for Low-Pressure and Gravity Casting, providing a full-service approach to the global two-wheel and four-wheel motor market. With integrated production and extensive expertise, we support our customers throughout the entire value chain: from product and process development, using simulations and fast prototyping, to mold construction and series production, ensuring quality, time optimization, and efficient production management.

LPDC & Gravity Casting

Precision, reliability and innovation for the automotive and industrial sectors.

Product types

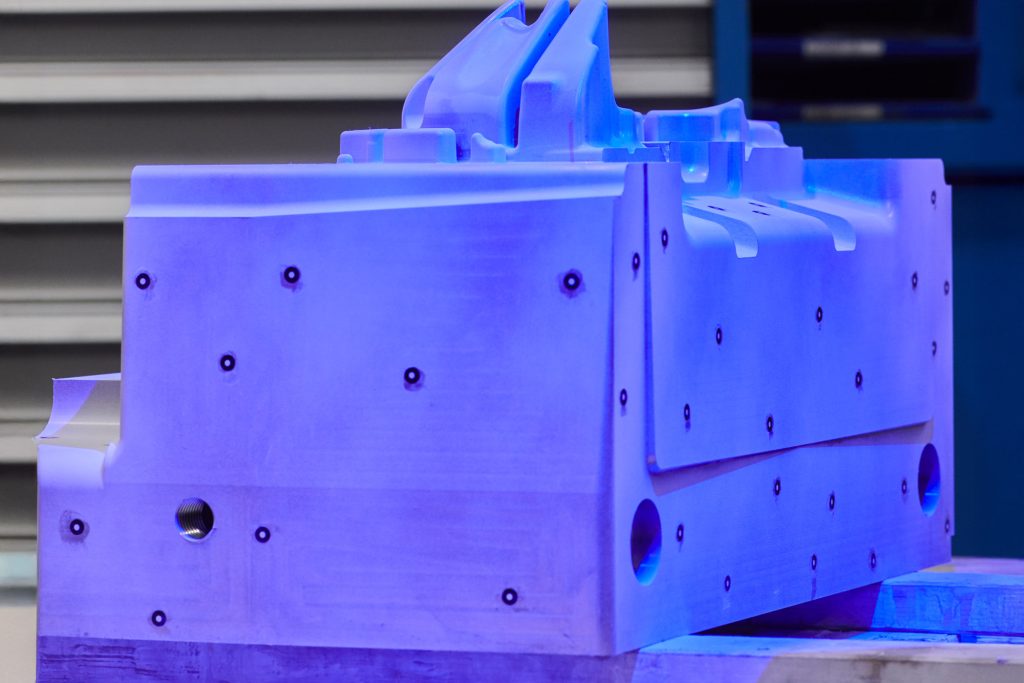

Low-pressure and gravity casting molds, core boxes

Alloys

Aluminum and cast iron.

Markets

Automotive, industrial.

Sizes

Suitable for LPDC and Gravity Casting systems of all sizes.

Production plants

Costamp LPDC & Gravity is based in Correggio (RE), in the heart of Motor Valley, with direct access to the Alunext foundry for real-time trials and validations.

Applications

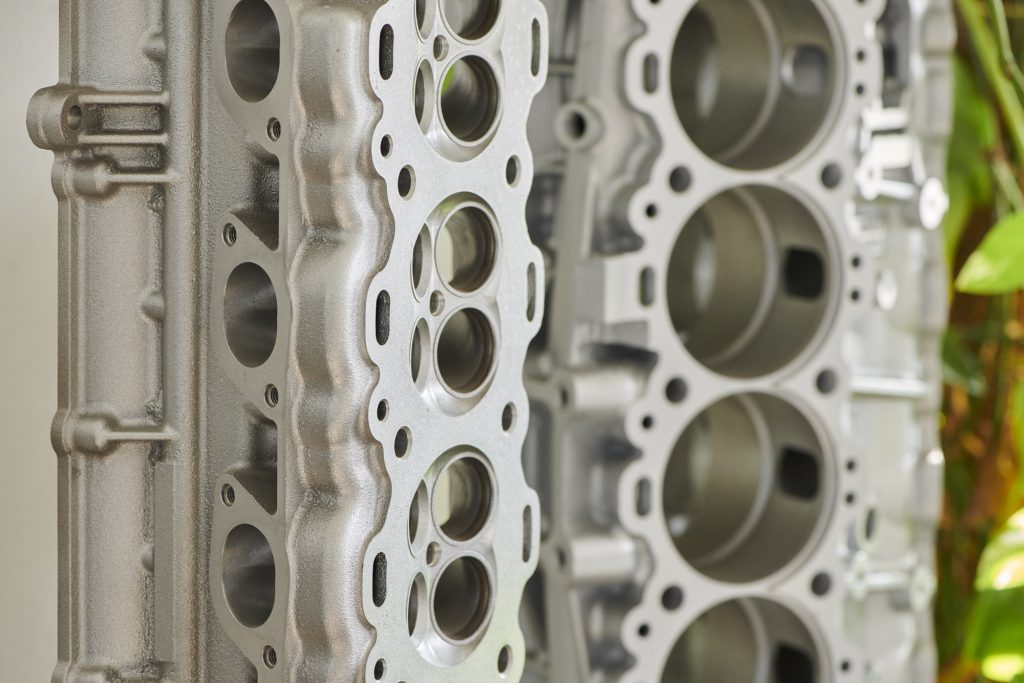

We manufacture molds for structural components, powertrain, and chassis:

- Cylinder heads

- Engine blocks

- Bed plates

- Crossmembers

- Suspension mounts

- Complete and partial subframes

- Knukles

- Battery trays

How we work

Project management

We manage every phase of the project with an integrated approach: from initial design to production, ensuring optimized and tailored solutions.

Design and construction

We use advanced software to simulate and optimize every phase of the casting process, reducing waste and improving production efficiency.

Prototyping and process development

Through our synergy with the in-house Alunext foundry, we provide sampling and validation services to ensure optimal results.

Series production and special batches

With a network of qualified partners, we offer complete solutions, from pre-series to large-scale production.

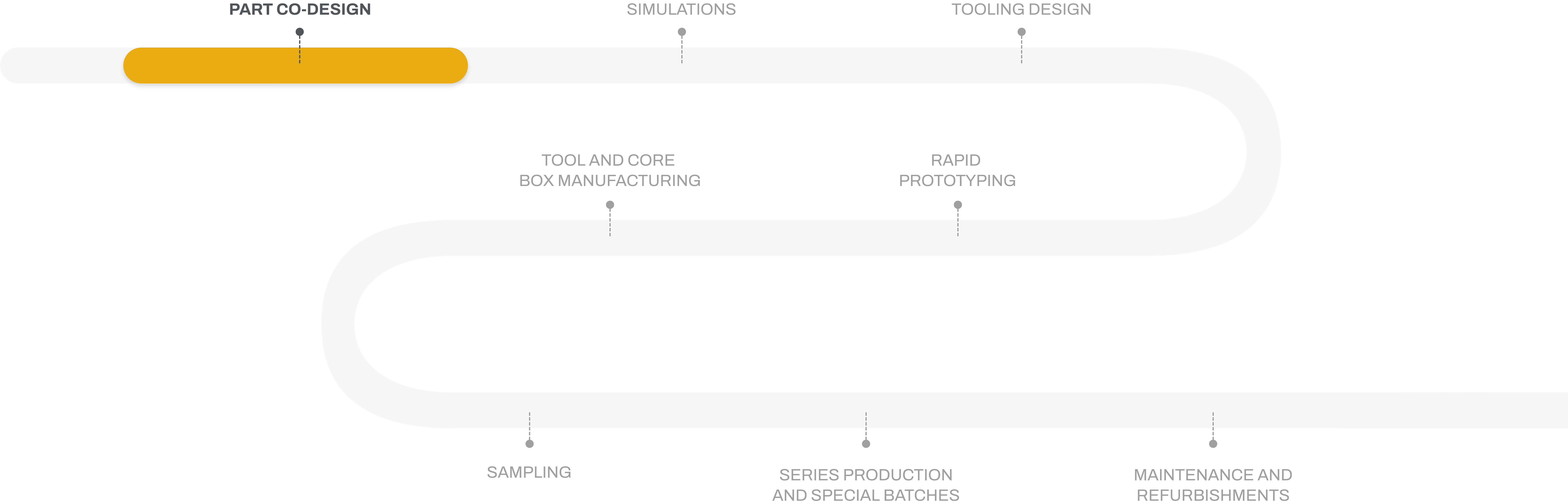

Our workflow