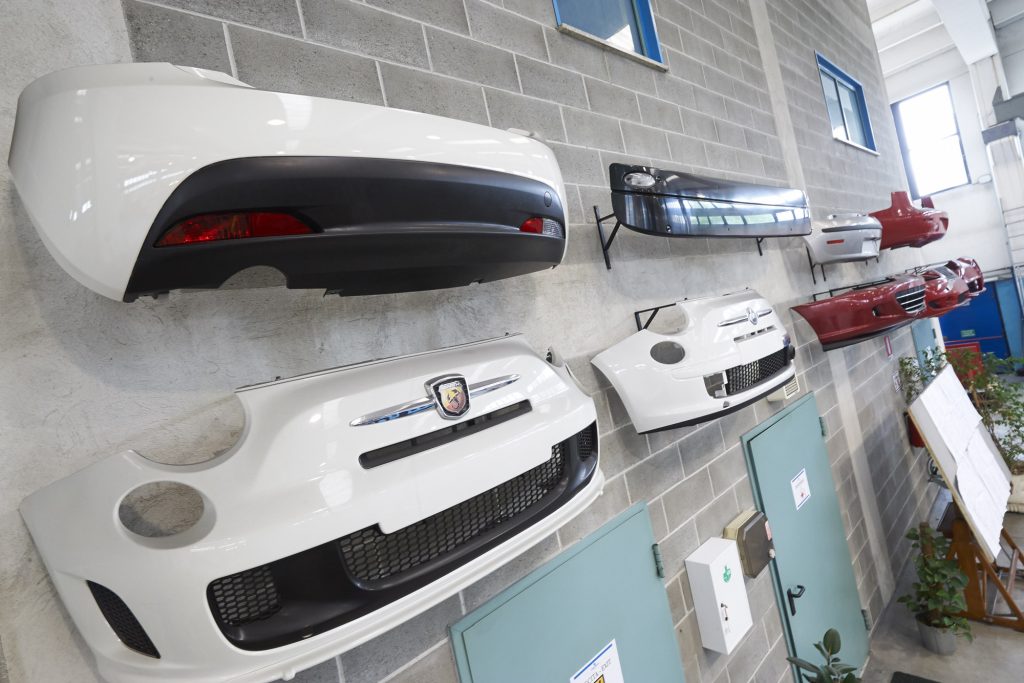

Costamp Plastic excels in the design and manufacturing of thermoplastic and thermosetting injection molds, offering customized solutions for mass production. Through an integrated approach that includes engineering services and advanced prototyping, we support our clients at every stage of the process.

With over 20 years of experience in the automotive sector, we develop cutting-edge technologies to provide high-quality, reliable, and high-performance solutions, suitable for a wide range of applications.