We are the ideal partner for the development of integrated prototyping solutions, offering full support both in the creation of equipment and in the production of raw and finished aluminum parts.

Innovation, speed, precision

The Applications

Pieces

- Rapid Prototyping

Sand castingPrototypes from solid

Tooling equipment

- Proto dies

Monoblock dies in hardened and tempered steelProduction die holder + prototype cavity inserts in hardened and tempered steel

- Sand cores

Supporting and measuring equipment

- Straightening fixtures

- Measurement and control gauges

- CNC machining jigs

- Heat treatment fixtures

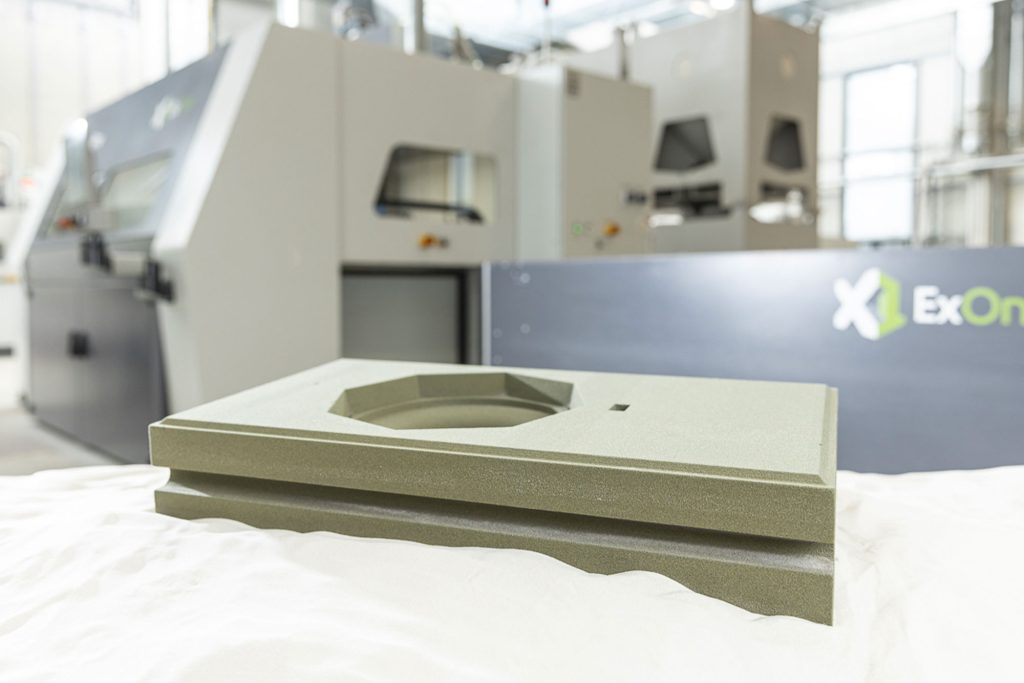

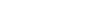

SuperProto

Thanks to our subsidiary SuperProto, we can produce printed cores in 3D using a 3D printer for core casting, with two work areas of 1800 x 1000 x 700 mm.

Prototype parts supply

Sand casting and/or machined from solid

As-cast, machined, and/or assembled

In small or large batches

Without shape limits

Unconstrained by size, thanks to the union of multiple cores

Our workflow

Costamp Prototyping offers an ecosystem of solutions to accelerate the development and validation of new products through the following operational flow: