PuzzleDie® is a groundbreaking mold design approach aimed at significantly increasing mold lifespan and improving the quality of produced parts.

Puzzle Die®

Long life to molds

Key advantages

of PuzzleDie®

-

Significant increase in tooling lifetime

We guarantee at least double the service life compared to traditional configurations.

-

Lower maintenance costs

The modular design allows for quick replacement of damaged inserts, minimizing downtime and reducing maintenance costs.

-

Optimized cooling system

Enhanced thermal management of the mold reduces the need for coolant lubricants.

-

Consistent casting quality throughout the mold’s lifespan.

-

Potential reduction in cycle time

The production cycle can be significantly shortened thanks to optimized solidification times and lubrication phases.

Horizon 2020 Programme

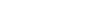

Costamp, thanks to active collaborations with FEM/CFD simulation providers, has studied and implemented a new design and construction technique for moulds in order to extend their service life like never before. The PuzzleDie® project has been funded through the EU Horizon 2020 Award for research and innovation.

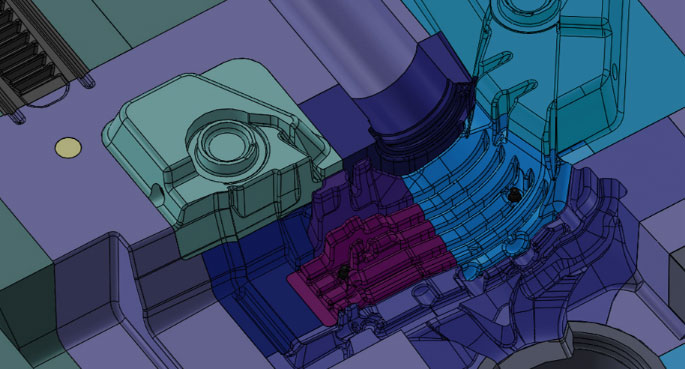

A concrete example

To better illustrate the advantages of the PuzzleDie® approach, here’s a real-world example applied to an existing project for a Steering Housing component. These are the results achieved:

- Mold life increased from 150,000 to 496,000 shots

- Cycle time was reduced from 85 to 72 seconds

- Maintenance cost savings reached 80%